CUSTOM MOLDED PARTS AND O-RINGS

Viton FDA O-Rings

Midwest Gasket proudly offers Viton FDA O-Rings, precision-engineered sealing components crafted from high-quality fluoroelastomer material. Designed to meet the exacting standards set by the U.S. Food and Drug Administration (FDA), these O-Rings are ideal for applications in food processing and pharmaceutical industries where stringent hygiene and safety compliance are paramount. With exceptional resistance to heat, chemicals, and oils, Midwest Gasket's Viton FDA O-Rings provide reliable and effective sealing, ensuring optimal performance in diverse and demanding environments. Choose Midwest Gasket for top-tier sealing solutions that meet FDA regulations and deliver unmatched quality in critical applications.

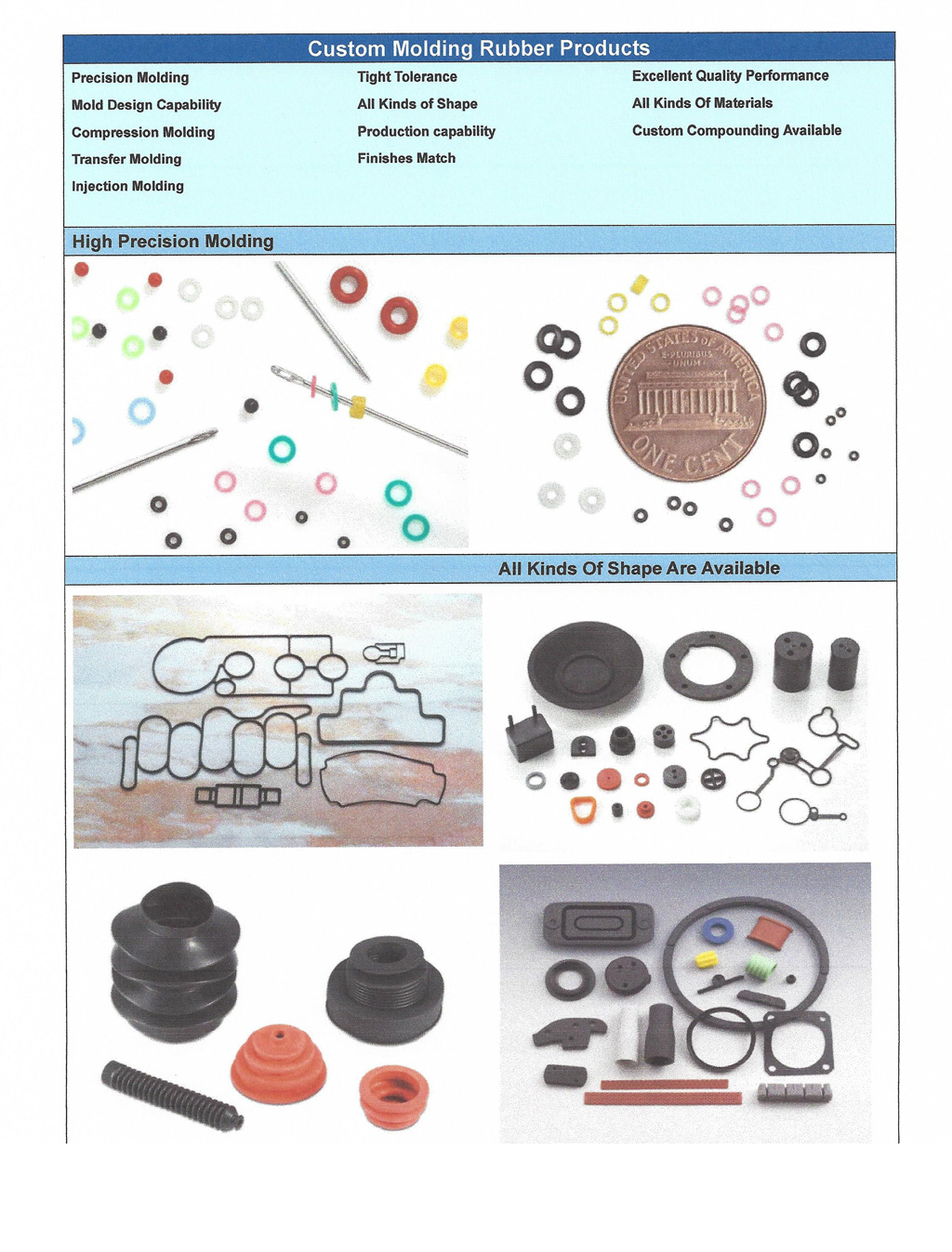

| Primary Capabilities | Standard and Custom O-Rings Molded & Extrusions Lathe Cutting |

| Manufacturing Process | Hot Vulcanizing Molded |

| Equipment/Capabilities | Clamshell Compression Molding Transfer Molding Injection Molding |

|

Types |

Standard Metric Quad Rings Splicing Kits Kalrez O-Rings Backup Rings Encapsulated Rings Miniature O-Rings |

| Material | Viton Nitrile (Buna) Neoprene Silicone EPDM PTFE FDA Approved Mil-Spec Fluorosilicone |

| Durometers | 40 - 90 "A" Scale |

| Temperature Range | -300 °F - 750 °F |

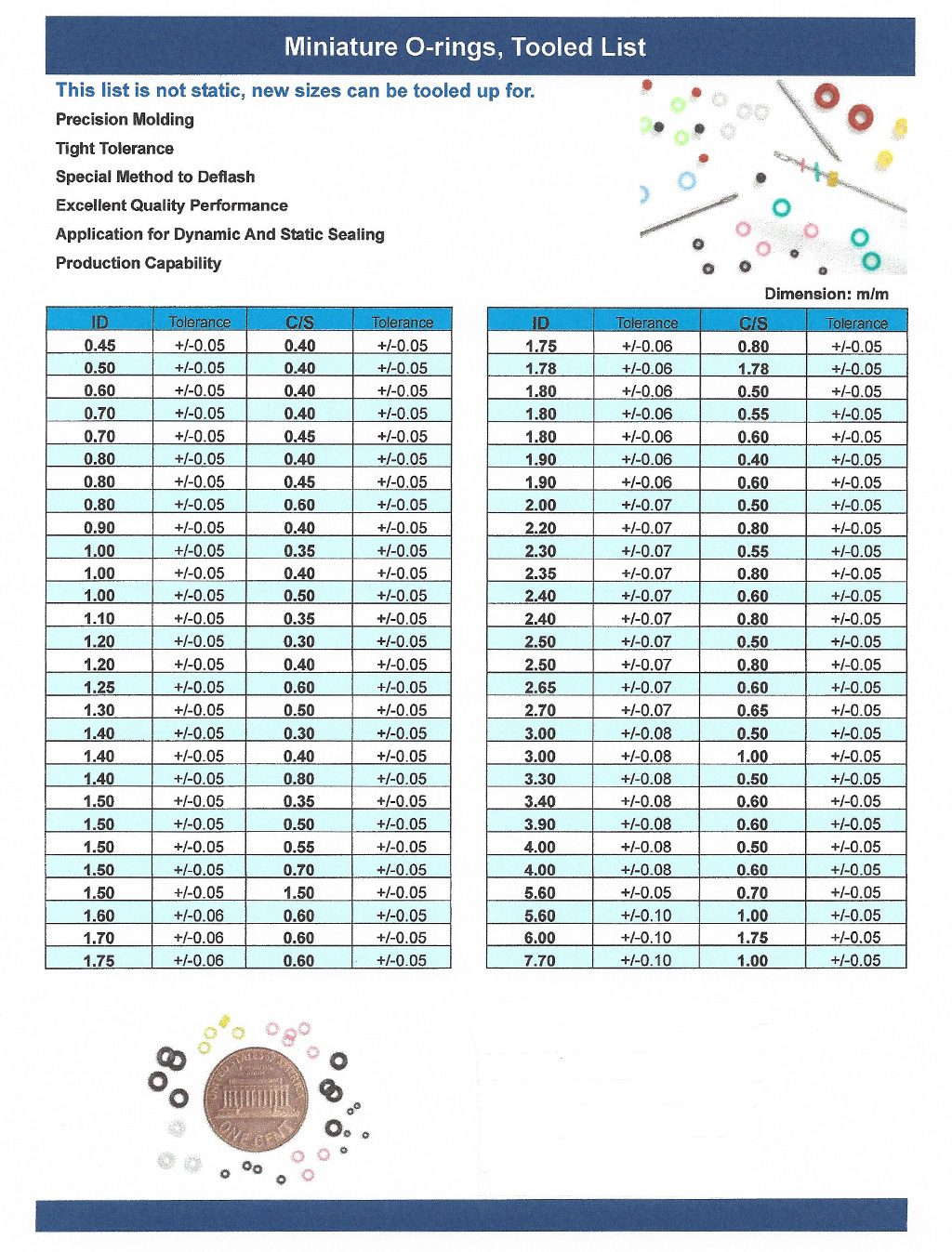

| Cross Section | .070" - 1" (Miniature O-Ring 0.0118” – 0.070”) 2 mm - 10 mm (Miniature O-Ring 0.30mm – 1.78mm) |

| Vulcanized Diameter | 3" - 300" or more (600mm x 600mm square) |

| Molded Diameter | .062" - 5" (540mm x540mm square) |

| Tolerance | ± .062" - .5" (or higher depending on size) (RMA A1 or ISO 3302-1 M1 Tolerance) |

| Inspection | Visual In-Process Final |

| Testing | Hardness Durometer Thickness Tolerance |

| Documentation | Material Certification (Material Data Sheet + IMDS) Inspection Report |

| Additional Services | Laser Tooling Assembly Special Packaging |

| Production Volume | 1 to 5,000,000 pcs |

| Typical Lead Time | 4 weeks first articles 6-8 weeks production 24 to 48 hours (Small Quantities) Just-In-Time Deliveries |

| Industry Focus | Automotive Airline Compressor Food and Beverage Military Municipalities Electrical Printing Replacement Parts Hydraulic |

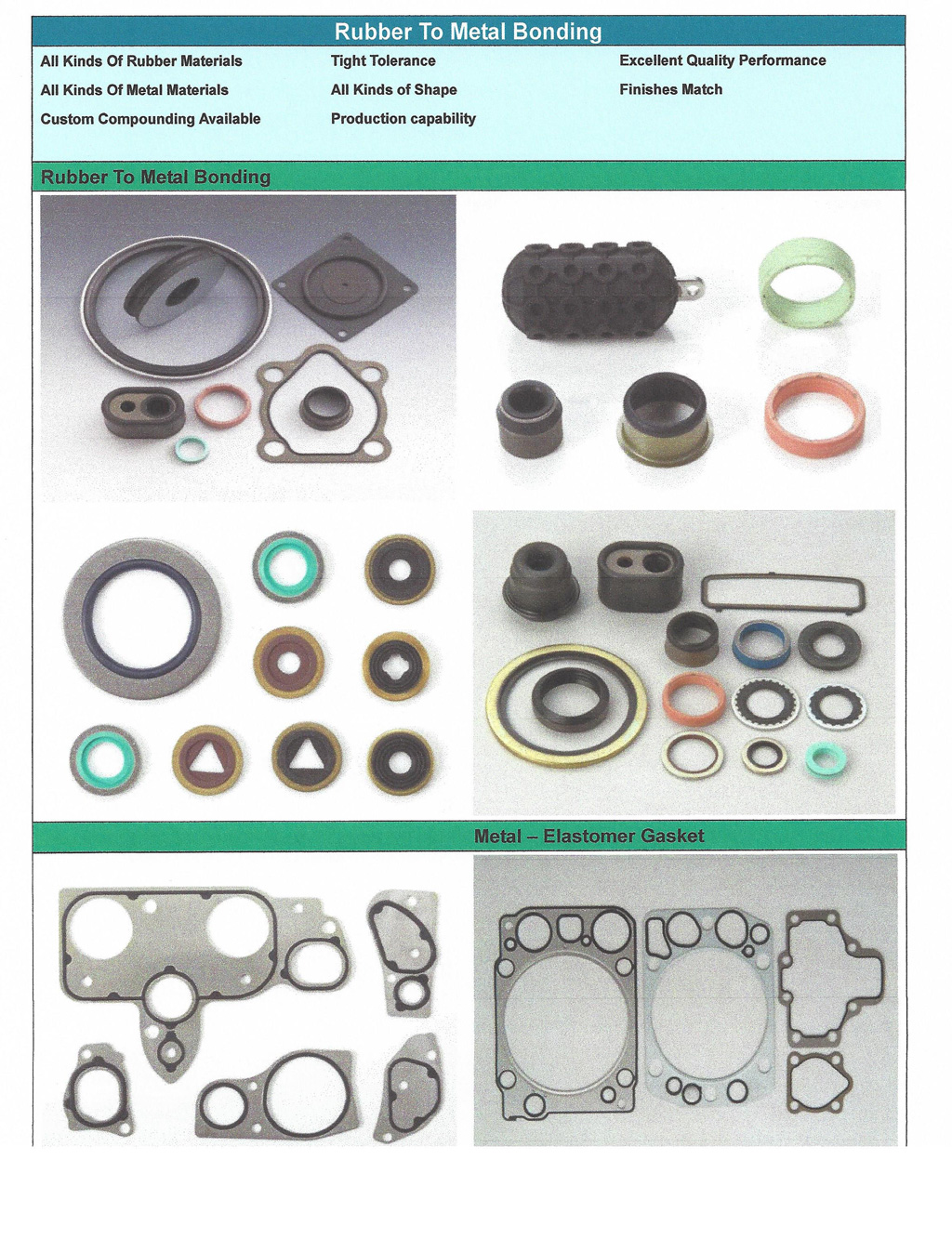

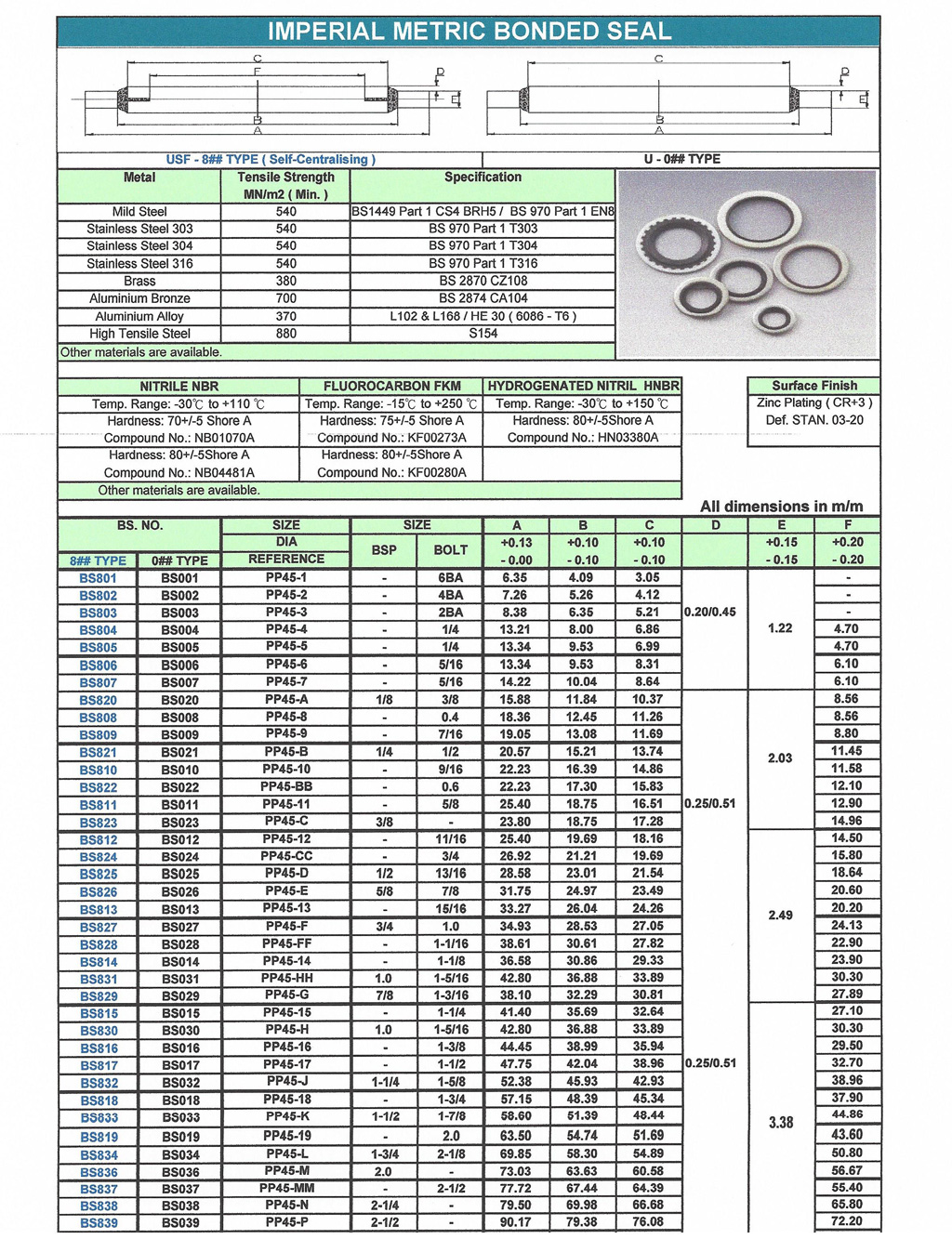

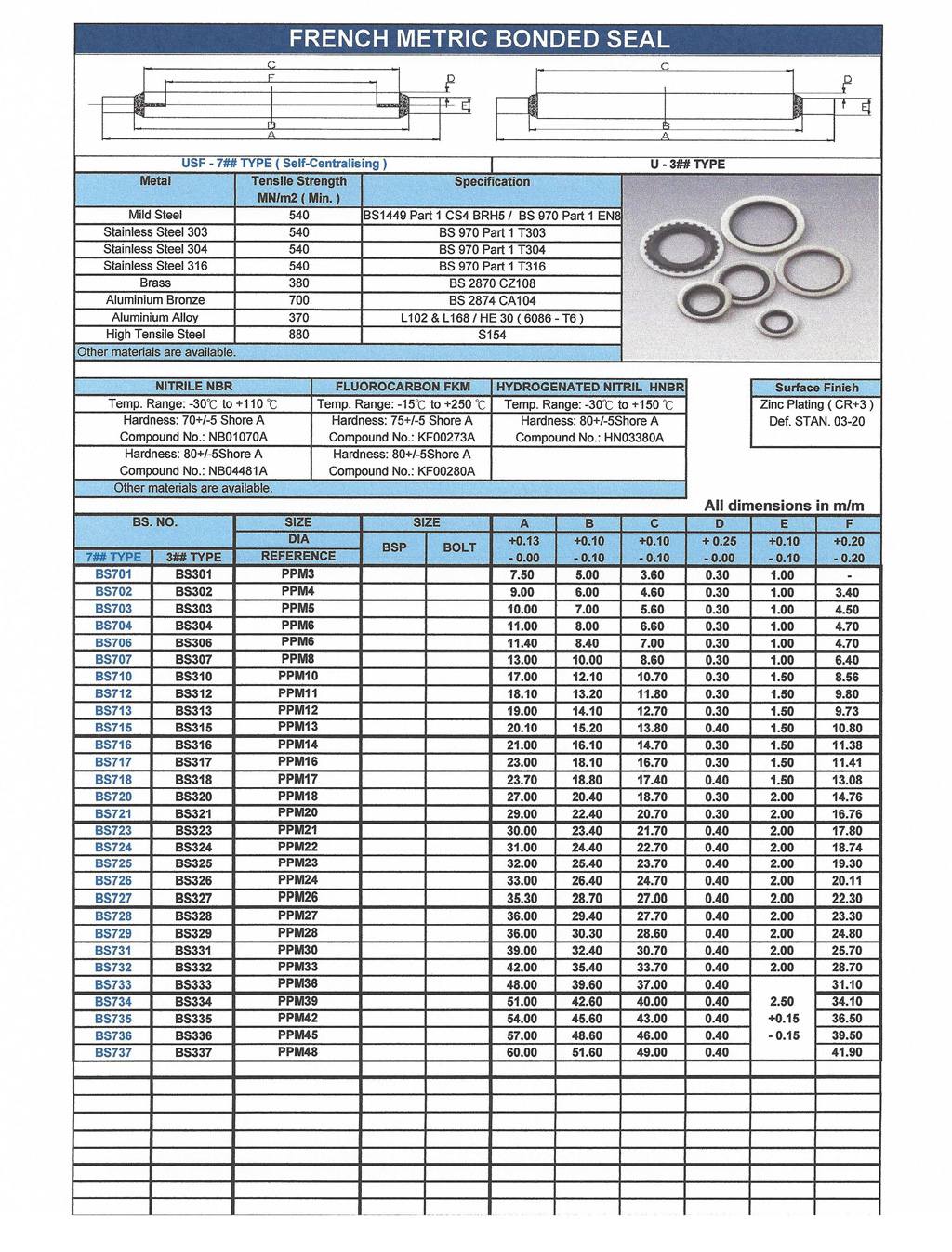

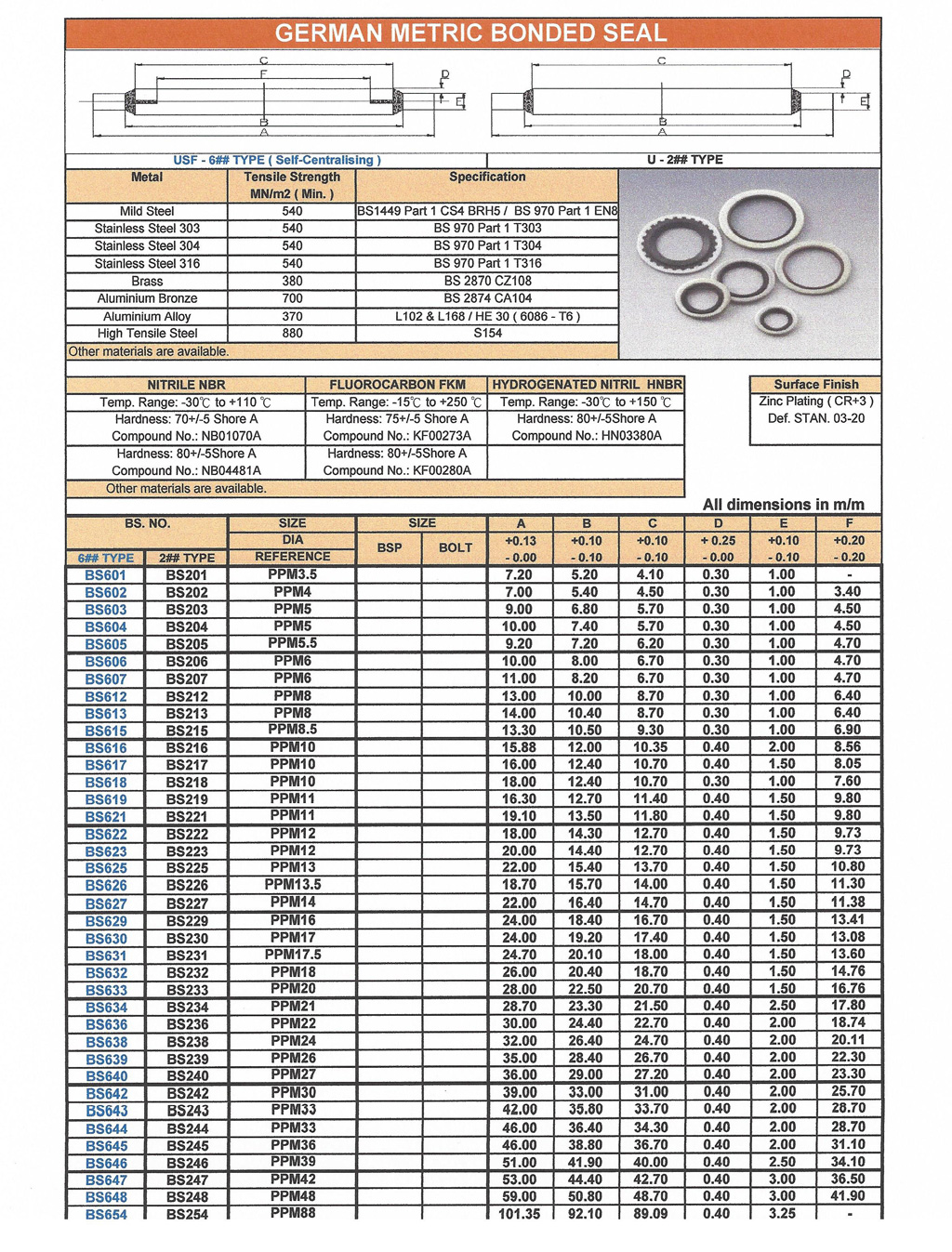

| Intended Applications | Gaskets Custom Molded Products Rubber to Metal Bonding Bonded Seals Grommets Washers Bumpers Spacers Anti-Vibration Pads Stoppers Rubber Plugs |

| Industry Standards | ASTM ANSI FDA OEM MIL-SPEC NSF UL |

| File Formats | AutoCAD (DWX, DWG) Teksoft ProCAD/CAM Adobe PDF |

Custom molded O-rings are specialized sealing solutions designed to meet the specific needs of various applications across industries. These O-rings can be tailored in terms of size, material, and design, ensuring optimal performance under different operating conditions. Below is a description of the types of custom molded O-rings, including their unique features and applications:

Standard O-Rings

Standard O-rings are the most common type of seals used for static and dynamic applications. They are available in various materials such as Nitrile, Silicone, and Viton, catering to a wide range of temperature and chemical resistance requirements. These O-rings are designed to meet international size standards, making them suitable for a multitude of sealing tasks.

Metric O-Rings

Metric O-rings are designed to fit the metric dimensions commonly used in international machinery and equipment. These O-rings come in various cross-sectional diameters and inner diameters, providing precise sealing solutions for applications requiring metric specifications.

Quad Rings

Quad rings, also known as X-rings, have a four-lobed design that offers twice the sealing surface compared to standard O-rings. This unique design provides better sealing efficiency and reduces the risk of twisting and rolling in dynamic applications. Quad rings are ideal for high-pressure sealing situations.

Splicing Kits

Splicing kits are designed for creating custom-sized O-rings on-site. These kits include lengths of O-ring cord, adhesive, and cutting tools, allowing for quick and efficient production of custom sizes that are not readily available. Splicing kits are perfect for emergency repairs or applications requiring unique O-ring sizes.

Kalrez O-Rings

Kalrez O-rings are made from a perfluoroelastomer material that offers exceptional chemical resistance and can withstand extreme temperatures. These O-rings are designed for demanding applications in the chemical processing, semiconductor, and aerospace industries, where other materials may fail.

Backup Rings

Backup rings are used in conjunction with O-rings to prevent extrusion in high-pressure applications. These rings are typically made from harder materials than the O-ring itself and are placed in the gland on the low-pressure side of the O-ring. Backup rings are essential for extending the life of O-rings in harsh conditions.

Encapsulated O-Rings

Encapsulated O-rings feature a core of elastomer, such as Silicone or Viton, encapsulated in a jacket of FEP (fluorinated ethylene propylene) or PFA (perfluoroalkoxy). This design combines the elasticity and sealing properties of the elastomer with the chemical resistance of the fluoropolymer jacket. Encapsulated O-rings are ideal for chemical and pharmaceutical applications.

Miniature O-Rings

Miniature O-rings are designed for sealing applications in small assemblies and precision instruments. These O-rings are available in a wide range of materials and offer the same variety of properties as their larger counterparts but are tailored for the unique challenges of miniaturized applications.

Each type of custom molded O-ring serves specific purposes, catering to different industry requirements, from standard sealing tasks to highly specialized applications requiring advanced materials and designs.

Midwest Gasket offers a wide selection of gasket materials to cater to various industrial applications, ensuring optimal performance and compliance with regulatory standards. Their materials include Viton, Nitrile (Buna), Neoprene, Silicone, EPDM, PTFE, and Fluorosilicone, as well as FDA-approved and Mil-Spec options for specialized needs. Each material is chosen for its unique properties, such as chemical resistance, temperature stability, and durability, making Midwest Gasket a reliable partner for your sealing solutions. Whether you require standard or custom gaskets, they provide high-quality materials to meet your specific demands.

Copyright © 2022. Midwest Gasket Corp. | All rights reserved. | Industrial Website Catalog by WYSIWYG Marketing